WEBINAR

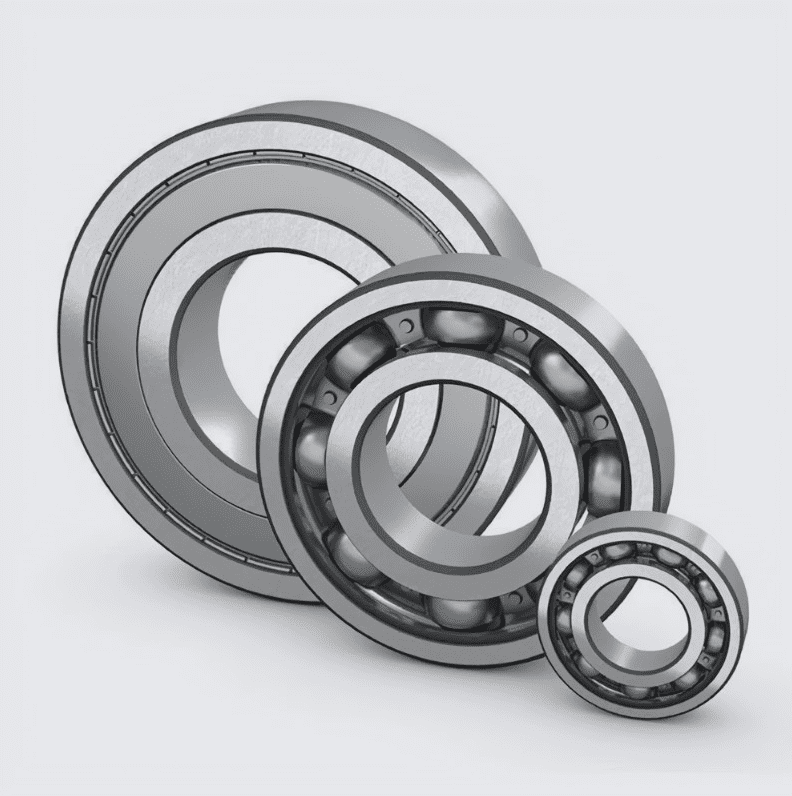

Deep Groove Ball Bearing

Learn More

Deep groove ball bearings are widely used in many high-speed applications such as electric motors, automotive wheels and high-speed machinery. However, in these applications, the bearing's performance is limited by its design and operating conditions. This article explores the performance and limitations of deep groove ball bearings in high-speed applications.

Low Friction: The design of deep groove ball bearing helps reduce running friction, which is especially important at high speeds.

Heat Generation: Although deep groove ball bearings have a low coefficient of friction, they still generate heat when operating at high speeds, which can affect bearing performance and life.

Accuracy and Stability: High-speed applications often require bearings with high accuracy and good operating stability.

Thermal Expansion: When operating at high speeds, thermal expansion of bearing components may affect clearance and preload, resulting in reduced performance.

Lubrication Challenges: High speeds can lead to lubricant breakdown or insufficient lubrication, requiring special attention to lubricant selection and lubrication system design.

Fatigue Life: High-speed operation may accelerate material fatigue and reduce the service life of the bearing.

Noise and Vibration: At high speeds, bearings may generate more noise and vibration, requiring special design to reduce these effects.

Proper Lubrication: Use the lubricant suitable for high-speed applications and ensure good lubrication conditions.

Precision Manufacturing: Ensures bearing manufacturing and assembly accuracy to improve performance at high speeds.

Material Selection: Use high-quality materials that can withstand high-speed applications, such as high-carbon chromium steel or ceramic materials.

Cooling System: Design an appropriate cooling system to control bearing temperature when it is necessary.

Although deep groove ball bearings have superior performance in high-speed applications, they also have some limitations. By selecting the appropriate materials, lubricants and design considerations, the high-speed performance of a bearing can be optimized, extending its service life and reducing the need for maintenance.

Understanding these performance characteristics and limitations is critical when selecting and using deep groove ball bearings in high-speed applications. Proper design and maintenance strategies can significantly improve bearing performance and reliability.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation