WEEYH experts believe that theoretical data can not be the only standard to testify a product, only the one that undergoes rigorous testing and meet the highest standards are truly qualified.

Safety is always WEEYH's first pursuit. Every other standard would be pointless if safety is not considered. Therefor WEEYH has invested lots of money and energy in testing and inspection.

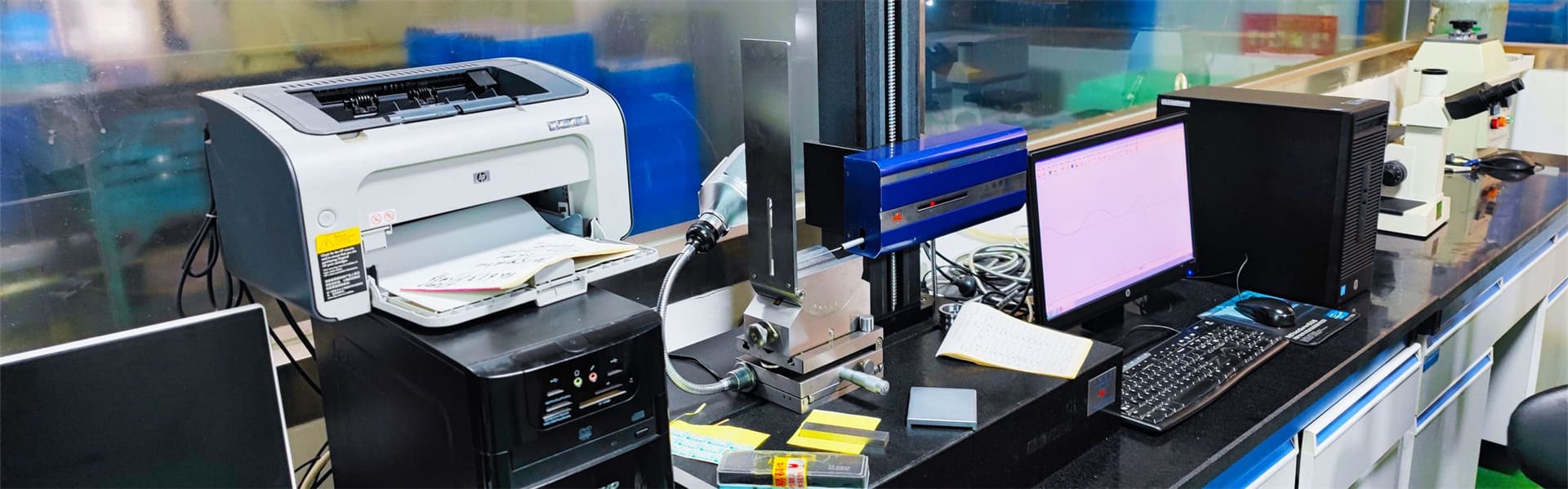

Apart from our own professional bearing testing laboratory, we rely on the top-notch testing equipment of China Bearing Research Institute, which has the corresponding testing process for each step from material analysis to finished product inspection. More than 30 kinds of testing equipment together built the safety net for WEEYH.

Working condition of test equipment in low temperature environmentUltrasonic flaw detection uses ultrasonic waves to non-destructively inspect internal defects and scars in materials or mechanical parts

Ultrasonic flaw detection uses ultrasonic waves to non-destructively inspect internal defects and scars in materials or mechanical parts

A punch can drill holes in metal surfaces.

Analyzing and testing the performance of clutch disc spring

Optical Testing of Metal Surfaces

Performance test of metal under high temperature environment

Performance test of metal under high temperature environment

Performance test of metal under high temperature environment

Clutch Metal Properties Test

Clutch Metal Cutting

Clutch Metal Cutting and Punching

Clutch metallographic analysis

Clutch Metallographic Observation

Metallographic experimental cutting of clutch metal

Simulated real-time working condition test

Metal flaw detection test

Clutch Metal Corrosion Test

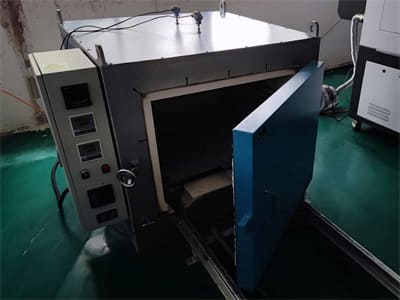

Test the operation of the equipment in a low temperature environment.

Test the operation of the equipment in a low temperature environment.

Test the operation of the equipment in a low temperature environment.

Analyze the force and elasticity of the clutch disc spring.

Perform an overload run test on the clutch disc springs.

Performance test of metal under high temperature environment

Performance test of metal under high temperature environment

Performance test of metal under high temperature environment

Clutch shock absorber overload torque test

Clutch Disc Spring Ultimate Compression Test

Clutch disc spring ultimate tension test

Alternating hot and cold impact test

Alternating hot and cold impact test

Product air tightness test

Friction Material Wear Test

Clutch drag torque test

Working test in simulated vacuum environment

Working test in simulated vacuum environment

Clutch Overfrequency Vibration Test

Clutch Overfrequency Vibration Test

This test can simulate various working modes of the tractor, conduct 20,000 working capacity tests on the clutch, and automatically generate comprehensive analysis data.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation