WEBINAR

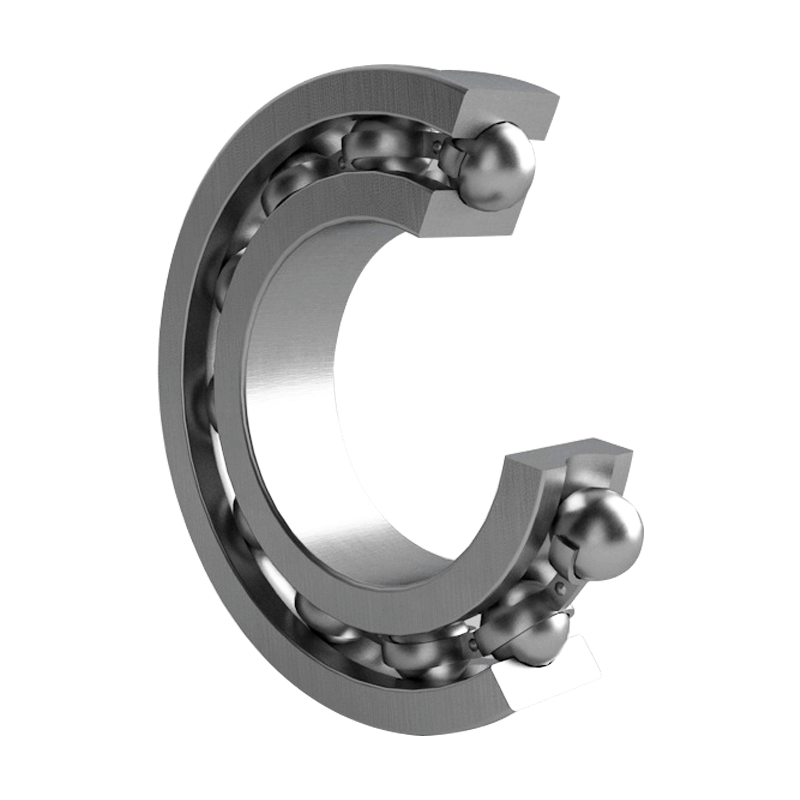

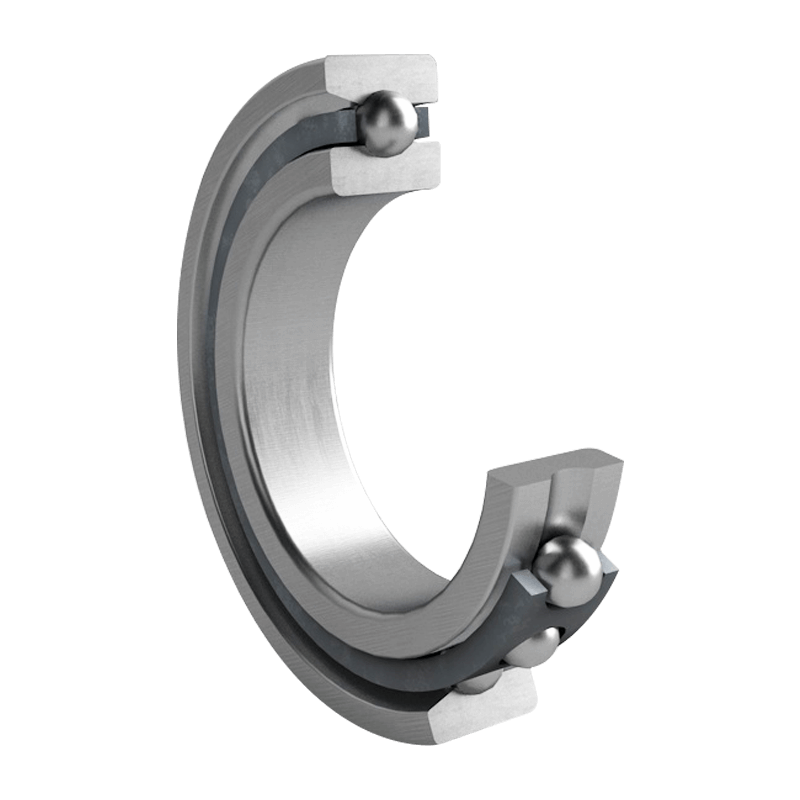

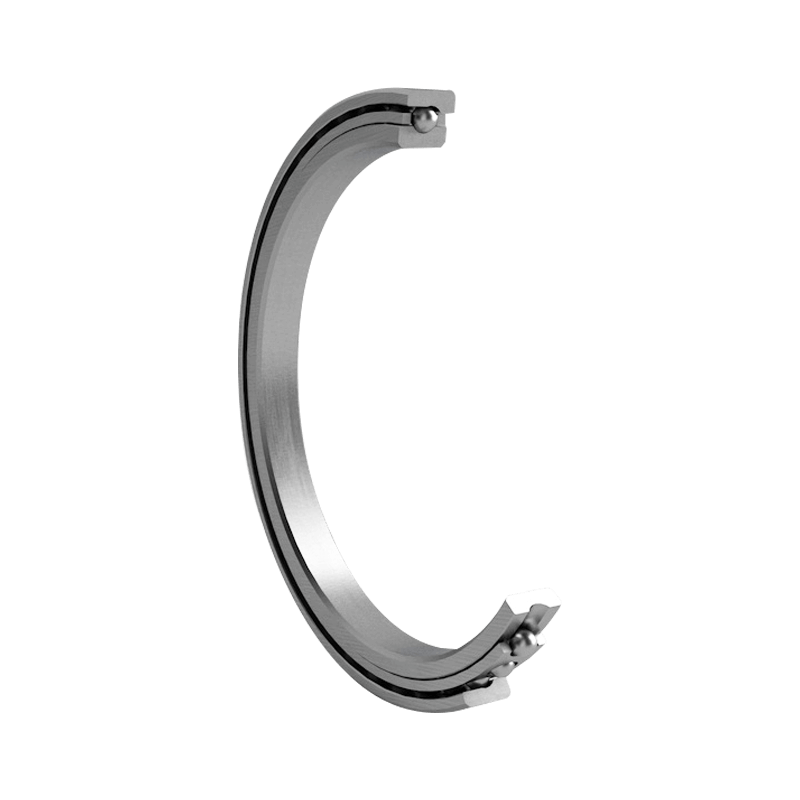

Deep Groove Ball Bearing

Learn More

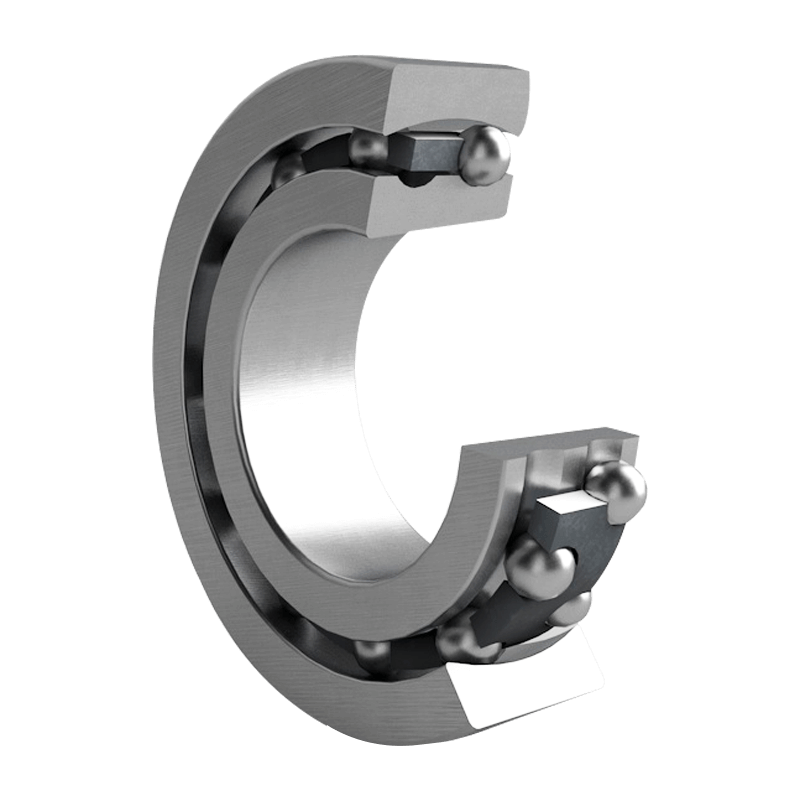

Deep groove ball bearings are one of the most common bearing types and are widely used in various mechanical equipment. It is known for its compact structure, strong load-bearing capacity and wide adaptability. This article will introduce the basic structure and working principle of deep groove ball bearings.

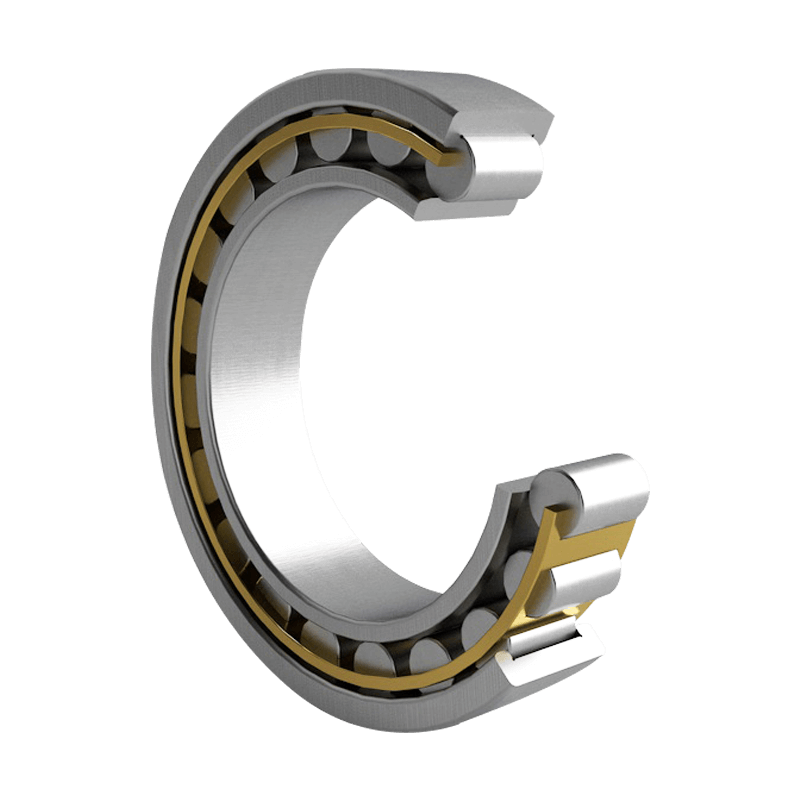

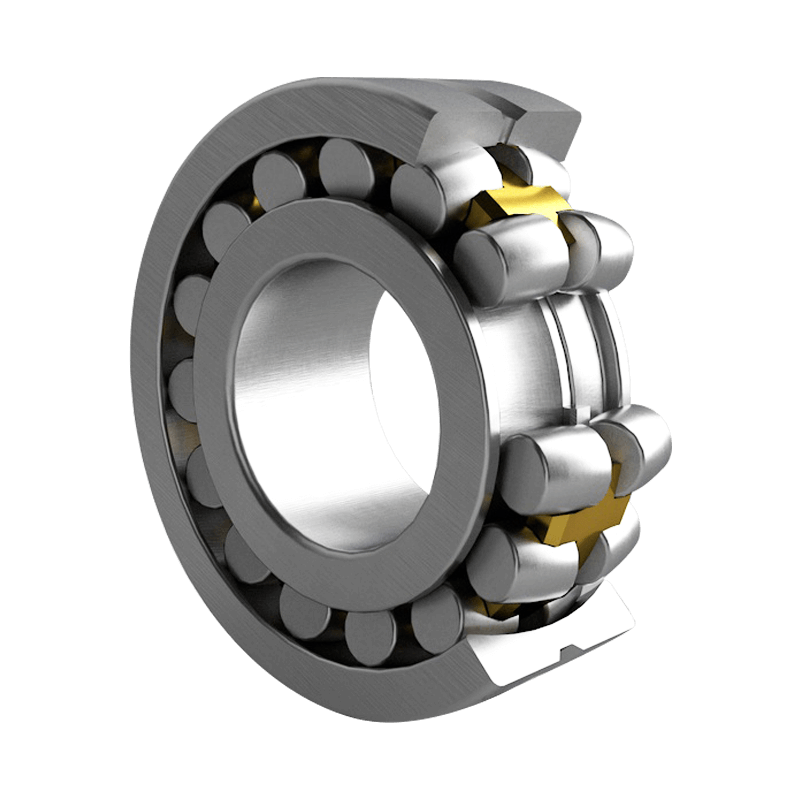

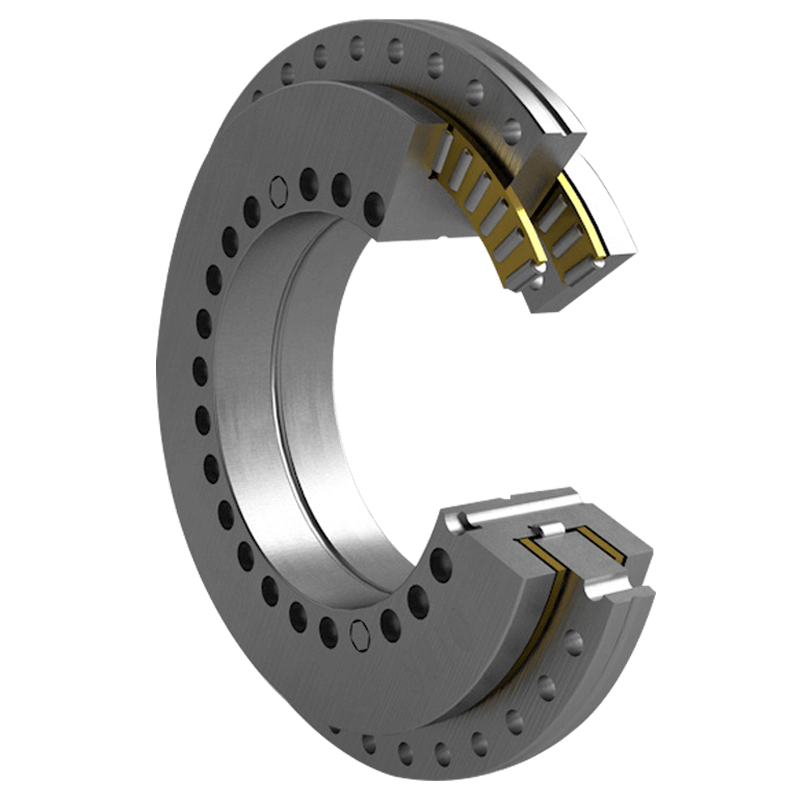

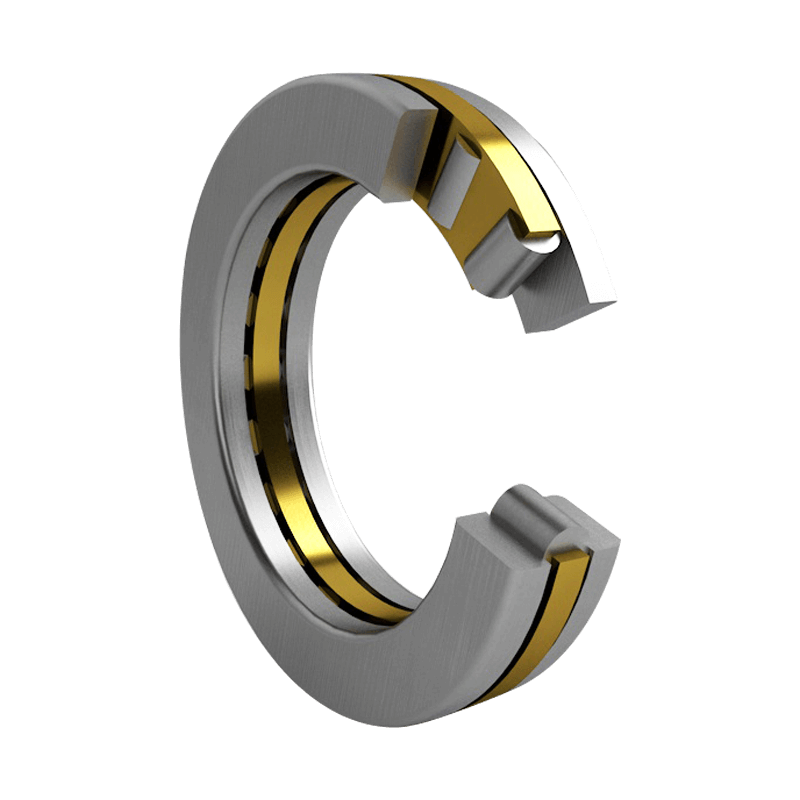

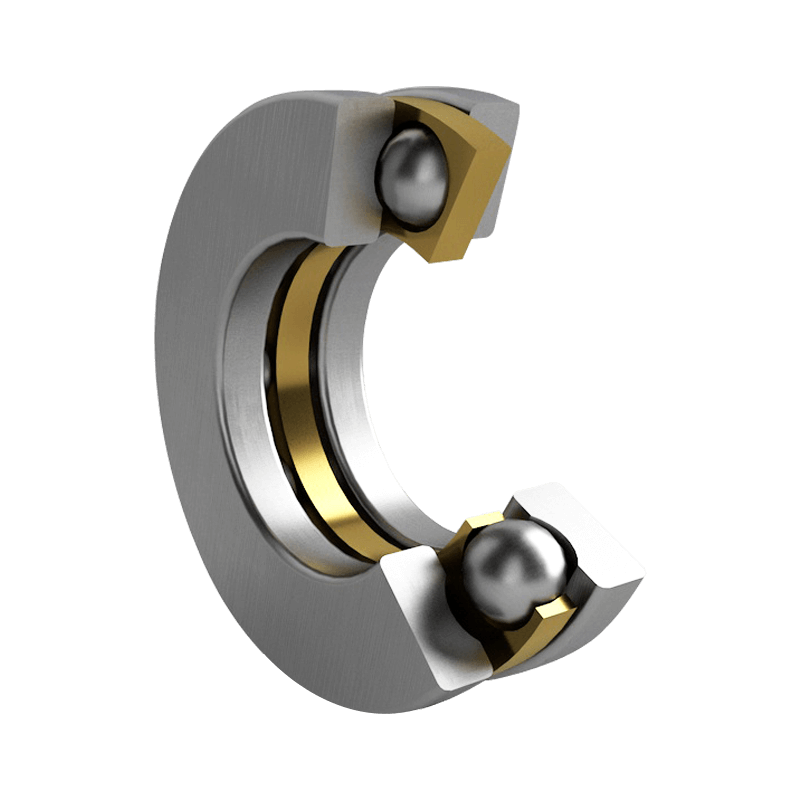

Deep groove ball bearings mainly consist of the following parts:

Inner Ring: The part that fits tightly with the shaft.

Outer Ring: The part that closely matches the bearing seat.

Rolling Elements (Balls): The balls are usually made of steel or ceramic material and located between the inner and outer rings.

Cage: It is used to keep the rolling elements equidistantly distributed and prevent them from contacting each other.

Sealing Cover/Shield (Optional): It is used to protect the inside of the bearing from dust and dirt, and also helps to retain lubricating oil or grease.

Reduce Friction: When relative rotation is required between the shaft and the housing, deep groove ball bearings can effectively reduce the friction between these two parts, which is achieved by rolling elements (balls) between the inner and outer rings.

Load Capacity: The unique design of deep groove ball bearings enables them to carry both radial loads (forces perpendicular to the shaft) and axial loads (forces along the shaft). The deep groove design means the ball can have a larger contact area, thereby increasing load-bearing capacity.

Smooth Rotation: Since rolling friction is smaller than sliding friction, deep groove ball bearings can achieve smooth, low-noise rotation.

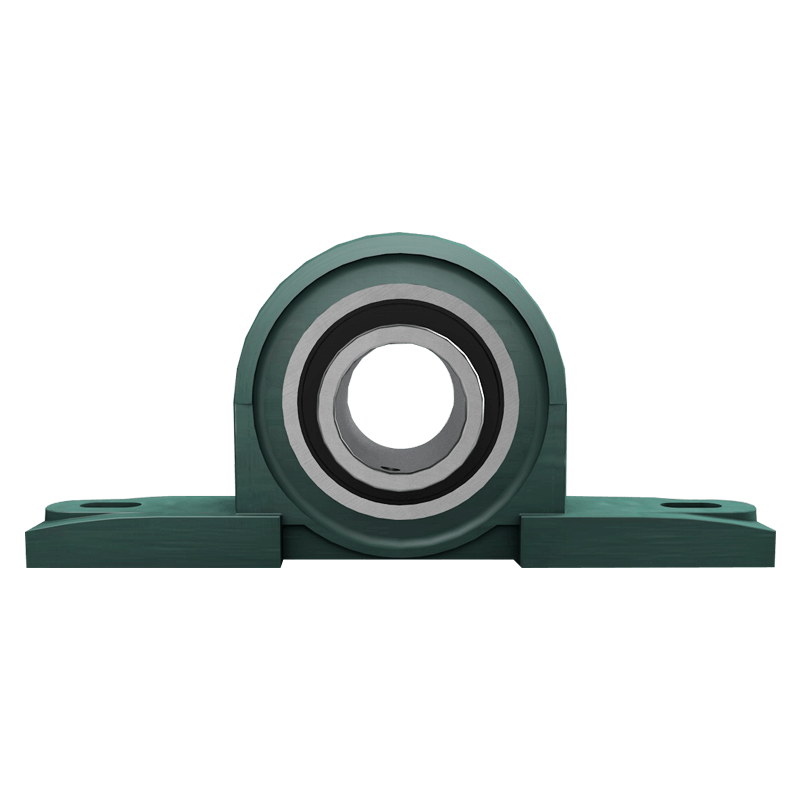

Deep groove ball bearings are very popular in many applications such as electric motors, automotive wheels, household appliances and industrial machinery due to their simple and effective design.

The simple yet efficient design of deep groove ball bearings makes them one of the most popular bearing types for a variety of applications. It combines the advantages of high load-bearing capacity, low friction and long-term reliability and is an integral part of modern machinery design.

Understanding the basic structure and working principles of deep groove ball bearings will help you better select and maintain such bearings to ensure the efficient operation of mechanical equipment.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation